Technology

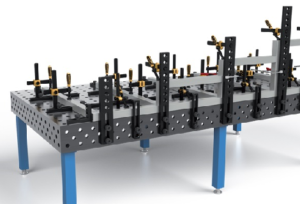

We focus on machine-aided production using the state-of-the-art technologies in area of CNC machining, i.e. laser cutting, bending and section and sheet metal machining. We provide complete surface treatment including wet and powder coating and cataphoresis. Besides manual welding, we also perform robotic welding. We inspect quality of our products in our in-house measurement centre.

PRIMARY PRODUCTION

Material cutting:

- Laser for sheet metals

- Laser for section steel

- Sawing

- Cutting

- CNC and conventional machining

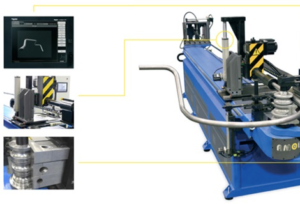

- CNC and conventional bending of sheet metals and sections

- Roller bending

- Pressing

PRODUCTION OF PLASTICS AND LAMINATED PLASTICS

PU-RIM technology:

- Reactoplastic material

- Closed injection moulding

- CNC trimming not required

- In-house design engineering (negative angles, holes, wall thickness difference)

- Mould lining (bolts, gaskets, metal lining, glass fibre, fabric reinforcement, other plastic reinforcement)

- 20% weight reduction

- Polyurethane can be filled with microfibre

- Resin moulds or aluminium moulds

- Technology suitable for low-volume series